What Types of Diesel Fuels Are Rejected in Afghanistan?

Afghanistan's fuel import sector plays a critical role in the country's economy and infrastructure, powering everything from transportation to electricity generation. However, stringent regulations enforced by the Afghan National Standards Authority (ANSA) ensure that only high-quality diesel enters the market. Recent updates to these standards have led to increased scrutiny and rejections at border points. This article explores the characteristics of approved diesel fuel in Afghanistan, delves into the reasons for rejections, and analyzes real-world test results from six rejected shipments. Drawing on official announcements, industry reports, and expert analyses, we aim to provide clarity for traders, buyers, and stakeholders navigating this evolving landscape.

Background on Afghanistan's Diesel Import Standards

Afghanistan relies heavily on imported diesel, primarily from neighboring countries like Iran, Turkmenistan, Iraq, And, Russia. The Afghan government, through ANSA and the Ministry of Industry and Commerce, regulates fuel quality to protect public health, reduce environmental pollution, and ensure compatibility with modern engines. Historically, diesel standards allowed sulfur content up to 5000 parts per million (ppm), but concerns over air quality and vehicle performance prompted reforms.

In June 2025, the High Standard Council approved six new standards and 51 testing procedures for petroleum products, including diesel, to enhance fuel quality across the sector. Effective July 1, 2025, a major update reduced the maximum allowable sulfur content in diesel from 5000 ppm to 2000 ppm (0.2% by mass), aligning with regional norms and aiming to curb emissions of sulfur dioxide, a key contributor to acid rain and respiratory issues. This change represents a significant tightening of regulations, with ANSA implementing more rigorous inspections at border checkpoints, resulting in higher rejection rates for substandard imports.

However, Afghanistan permits imports under two tiered standards to accommodate varying market needs: one with sulfur content below 2000 ppm and a stricter one below 1500 ppm. These tiers allow flexibility for traders while progressively pushing toward cleaner fuels. The 1500 ppm standard is often applied to premium or urban-use diesel, where environmental impacts are more pronounced. Despite the focus on sulfur, it is not the sole parameter; approvals hinge on a comprehensive set of physical, chemical, and performance characteristics.

Key Characteristics of Approved Diesel Fuel in Afghanistan

Approved diesel must comply with ANSA's national norms, which draw from international benchmarks like ASTM standards and EN590. These specifications ensure the fuel is safe, efficient, and environmentally sound. Below is a summary of the primary parameters for the 2000 ppm sulfur standard (with notes on variations for the 1500 ppm tier where applicable):

| Parameter | Unit | Test Method | Limit (2000 ppm Standard) | Notes on 1500 ppm Standard |

|---|---|---|---|---|

| Sulfur Content | % mass | ASTM D2622 or D4294 | Max 0.2 (2000 ppm) | Max 0.15 (1500 ppm) |

| Cetane Number | - | ASTM D613 | Min 51 | Same |

| Cetane Index | - | ASTM D976 | Min 51 (calculated) | Same |

| Density @ 15°C | kg/m³ | ASTM D1298 / D4052 | 820–860 | Same |

| Flash Point | °C | ASTM D93 | Min 55 | Same |

| Kinematic Viscosity @ 40°C | mm²/s | ASTM D445 | 1.8–6 | Same |

| Distillation: 10% Recovered | °C | ASTM D86 | 180–230 | Same |

| Distillation: 50% Recovered | °C | ASTM D86 | 230–280 | Same |

| Distillation: 90% Recovered | °C | ASTM D86 | 280–340 | Same |

| Distillation: 96% Recovered | °C | ASTM D86 | Max 360 | Same |

| Distillation Residue | % | ASTM D86 | Max 2 | Same |

| Color | - | Visual | Clear and bright (1a) | Same |

| Copper Corrosion @ 50°C | - | ASTM D130 / GOST 32329 | 1a | Same |

| Cloud Point | °C | ASTM D2500 | Max -7 | Same (winterized variants may vary) |

| Cold Filter Plugging Point (CFPP) | °C | ASTM D4939 | Max -10 | Same |

| Water Content | mg/kg | ASTM D6304 | Max 200 | Same |

These parameters ensure the fuel ignites properly (high cetane), flows well in cold weather (low cloud point and CFPP), and minimizes engine corrosion and emissions. For the 1500 ppm tier, the lower sulfur limit reduces particulate matter in exhaust, making it suitable for areas with stricter pollution controls. Non-compliance in any area can lead to rejection, as ANSA tests samples at entry points using accredited labs.

Euro III equivalent standards have also been referenced in some reports, which would imply even lower sulfur (350 ppm), but current implementations focus on the 1500–2000 ppm range as a transitional step. Global maps from 2025 indicate Afghanistan in the 2000 ppm or below category, reflecting ongoing progress toward cleaner fuels.

Why Are Diesel Shipments Rejected? Insights from Real Test Results

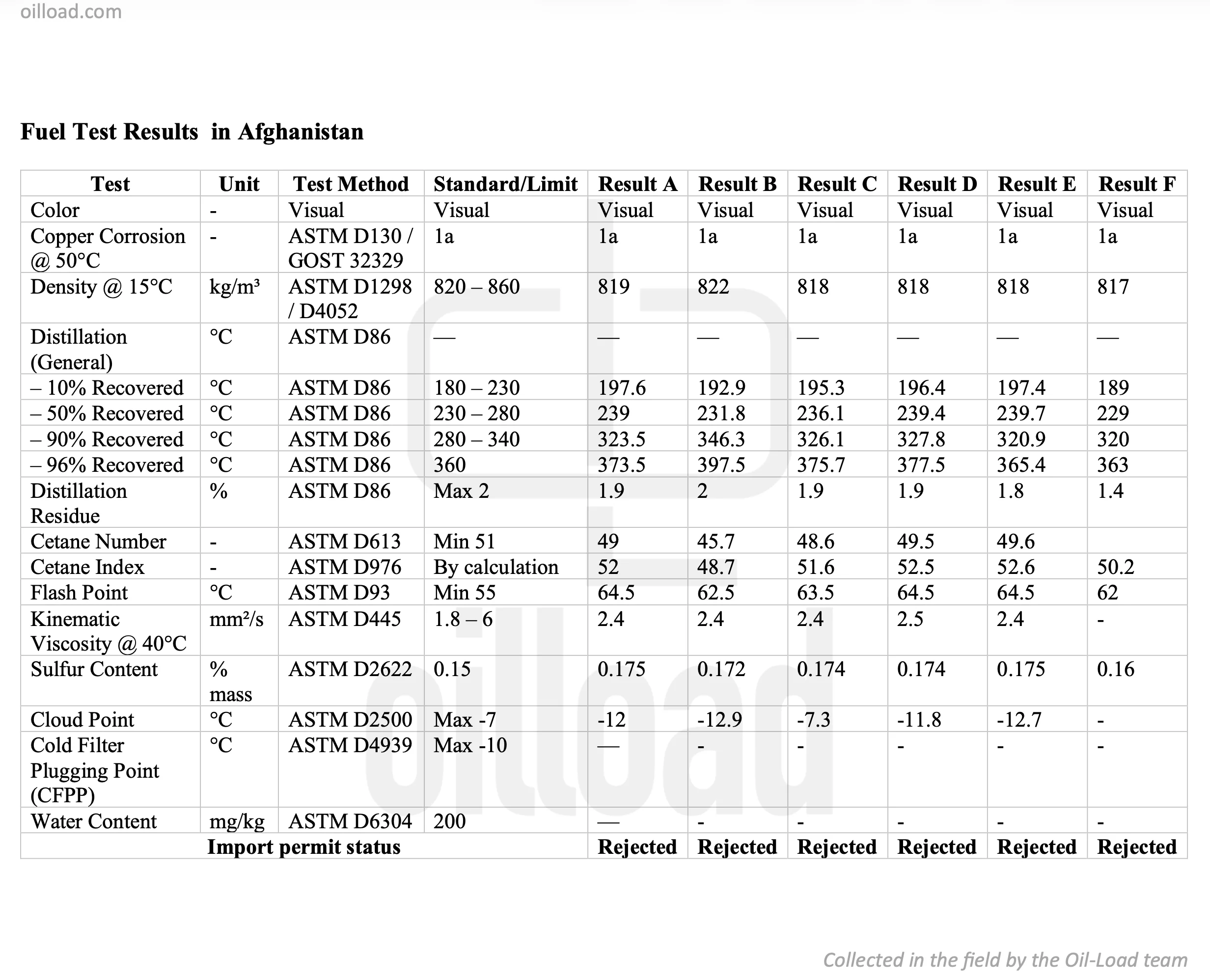

Despite clear guidelines, many importers face rejections due to misunderstandings or substandard sourcing. Sulfur is a common culprit, but failures often span multiple parameters. To illustrate, the Oil-Load field team reviewed six recent test results from shipments rejected by ANSA. All were intended for the stricter 1500 ppm standard (limit: 0.15% sulfur) but failed on various fronts. Below is a compiled table of the results:

| Test | Unit | Test Method | Standard/Limit | Result A | Result B | Result C | Result D | Result E | Result F |

|---|---|---|---|---|---|---|---|---|---|

| Color | - | Visual | Clear and bright | Visual | Visual | Visual | Visual | Visual | Visual |

| Copper Corrosion @ 50°C | - | ASTM D130 / GOST 32329 | 1a | 1a | 1a | 1a | 1a | 1a | 1a |

| Density @ 15°C | kg/m³ | ASTM D1298 / D4052 | 820–860 | 819 | 822 | 818 | 818 | 818 | 817 |

| Distillation: 10% Recovered | °C | ASTM D86 | 180–230 | 197.6 | 192.9 | 195.3 | 196.4 | 197.4 | 189 |

| Distillation: 50% Recovered | °C | ASTM D86 | 230–280 | 239 | 231.8 | 236.1 | 239.4 | 239.7 | 229 |

| Distillation: 90% Recovered | °C | ASTM D86 | 280–340 | 323.5 | 346.3 | 326.1 | 327.8 | 320.9 | 320 |

| Distillation: 96% Recovered | °C | ASTM D86 | Max 360 | 373.5 | 397.5 | 375.7 | 377.5 | 365.4 | 363 |

| Distillation Residue | % | ASTM D86 | Max 2 | 1.9 | 2 | 1.9 | 1.9 | 1.8 | 1.4 |

| Cetane Number | - | ASTM D613 | Min 51 | 49 | 45.7 | 48.6 | 49.5 | 49.6 | - |

| Cetane Index | - | ASTM D976 | By calculation | 52 | 48.7 | 51.6 | 52.5 | 52.6 | 50.2 |

| Flash Point | °C | ASTM D93 | Min 55 | 64.5 | 62.5 | 63.5 | 64.5 | 64.5 | 62 |

| Kinematic Viscosity @ 40°C | mm²/s | ASTM D445 | 1.8–6 | 2.4 | 2.4 | 2.4 | 2.5 | 2.4 | - |

| Sulfur Content | % mass | ASTM D2622 | Max 0.15 | 0.175 | 0.172 | 0.174 | 0.174 | 0.175 | 0.16 |

| Cloud Point | °C | ASTM D2500 | Max -7 | -12 | -12.9 | -7.3 | -11.8 | -12.7 | - |

| Cold Filter Plugging Point (CFPP) | °C | ASTM D4939 | Max -10 | - | - | - | - | - | - |

| Water Content | mg/kg | ASTM D6304 | Max 200 | - | - | - | - | - | - |

| Import Permit Status | - | - | Approved | Rejected | Rejected | Rejected | Rejected | Rejected | Rejected |

Analysis of Rejections

- Sulfur Content: All samples exceeded the 1500 ppm limit (0.15%), ranging from 0.16% to 0.175% (1600–1750 ppm). Under the 2000 ppm standard, these might pass, but as they were submitted under the stricter tier, they failed. High sulfur often stems from sourcing unrefined or blended fuels from unregulated suppliers.

- Cetane Number: Universally low (45.7–49.6 vs. min 51), indicating poor ignition quality. This can cause engine knocking, reduced efficiency, and higher emissions—common in cheaper, aromatic-heavy diesels.

- Distillation Properties: Several exceeded limits, e.g., 96% recovered temperatures up to 397.5°C (vs. max 360°C), suggesting heavier fractions that could lead to carbon deposits. Sample B's 90% recovered at 346.3°C also breached the 340°C cap.

- Density: Samples A, C, D, E, and F fell below 820 kg/m³ (817–819), potentially affecting energy content and pump calibration.

- Other Parameters: Flash point, viscosity, and corrosion met standards, but cumulative failures sealed the rejections.

These cases highlight that while sulfur grabs headlines, holistic compliance is essential. Rejections have surged post-July 2025, with reports of tankers turned back at borders like Nimroz. Importers often doubt results due to lab variations or border delays, but ANSA's accredited testing aims for transparency.

Common Pitfalls and Advice for Buyers

Rejections typically arise from sourcing low-cost fuels that prioritize price over quality, inadequate blending, or misrepresentation of standards. To avoid issues:

- Verify supplier certifications against ANSA norms.

- Request pre-shipment testing using ASTM methods.

- Opt for the appropriate tier (1500 ppm for sensitive applications).

- Stay updated via ANSA's website or industry portals like Oil Load.

As Afghanistan advances toward lower-sulfur fuels—potentially Euro III levels (350 ppm) in the future—these standards will foster a cleaner, more reliable energy sector. For traders, understanding these nuances is key to successful imports and contributing to national development.